Expanding the Role of AI and Simulation in the Space Industry

Artificial intelligence (AI) is revolutionizing industries worldwide, including the space sector, where its potential continues to grow to meet the increasing complexity of modern systems. As engineers integrate AI into space technologies, they face new challenges, particularly in verification and validation. These challenges stem partly from the dependence of AI on high-quality data. Poor data—whether insufficient, inaccurate, or biased—can compromise an AI model's effectiveness, leading to unreliable outcomes.

-

The Intersection of AI and Simulation in Space

AI and simulation are converging in three key ways within the space industry:

- Addressing Insufficient Data: Simulation models can generate synthetic data to fill gaps that are too costly or difficult to address through real-world collection.

- Creating Reduced-Order Models: AI is being used to approximate complex, computationally expensive simulations, streamlining workflows.

- Enhancing Embedded Systems: AI models are integrated into embedded systems for applications such as supervisory logic, signal processing, and embedded vision, where simulation plays a pivotal design role.

These advancements demonstrate how simulation and AI address challenges related to time, reliability, and data quality in space applications.

Key Challenges and Solutions

Challenge 1: Data for Training and Validating AI Models

Acquiring clean, well-organized data for AI training and validation is particularly difficult for space missions. Since most AI models are static, operating on fixed parameters, they risk underperforming when exposed to new, unaccounted-for data. Without robust datasets, AI projects can falter, leading to wasted time troubleshooting poorly performing models.

Simulation offers a powerful solution by generating synthetic data, which can be used to augment training datasets. This approach offers several advantages:

- Cost-Effectiveness: Computational simulations are often less expensive than physical experiments, avoiding costly hardware errors.

- Controlled Environments: Engineers can simulate conditions that are dangerous, impractical, or impossible to recreate physically.

- Detailed Insights: Simulations provide access to internal states of systems, offering a deeper understanding when debugging AI models.

By iteratively simulating data, updating models, and refining predictions, engineers improve AI reliability. Validation through real-world testing ensures simulated environments align with reality. Tools like Simulink and MATLAB streamline this process, enabling data generation, model building, and simulation within a single platform.

Challenge 2: Approximating Complex Systems with AI

In applications where algorithms interact with physical systems—such as controlling hydraulic valves or wireless communication channels—engineers rely on simulations for iterative design and testing. These simulation models, often termed plant models or environment models, aim to replicate physical systems with high accuracy.

Historically, creating these high-fidelity models was time-intensive, and their computational demands limited rapid iteration. AI addresses this bottleneck by approximating these models with reduced-order representations. In some cases, AI models are directly trained on experimental data, bypassing physics-based modeling altogether.

Reduced-order AI models are computationally efficient, allowing engineers to explore more design alternatives. Physics-based models can still validate the final designs. Recent advancements integrate AI with embedded physical principles, enabling models that retain critical system characteristics while approximating other aspects using data-driven techniques.

Challenge 3: AI for Algorithm Development

Simulations have become indispensable for engineers designing algorithms for control systems, virtual sensors, and other applications. Traditional methods, such as linear models and Kalman filters, are limited in their ability to handle the nonlinear behavior of real-world systems. AI offers a flexible alternative, capable of modeling complex dynamics.

For instance, AI can predict unobservable states from observed data, integrating these predictions into system algorithms. However, embedding AI models into physical hardware presents unique challenges, including constraints on memory, performance, and programming languages. Engineers must balance trade-offs between model accuracy and on-device efficiency.

Verification and validation requirements further restrict AI’s early applications to non-critical systems. However, emerging techniques like reinforcement learning are pushing boundaries, enabling the development of entire control strategies. These methods are being explored for tasks such as robotic operations, autonomous systems, and planetary landings, but they require accurate environment models and extensive computational resources.

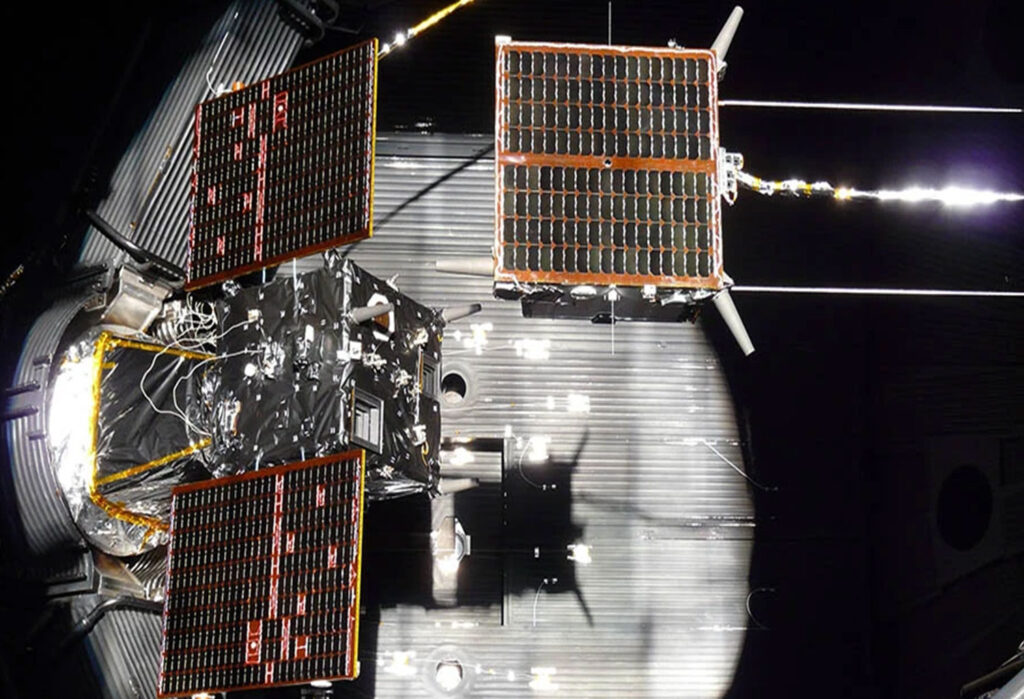

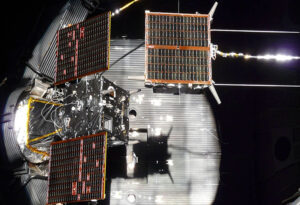

AI is also proving valuable in applications like embedded vision, signal processing, and wireless communication. For example, generating synthetic imagery for Rendezvous, Proximity Operations, and Docking (RPOD) scenarios allows engineers to train perception algorithms effectively.

The Future of AI and Simulation in Space

As systems grow increasingly complex, AI and simulation will play even greater roles in space exploration and technology development. Tools like MATLAB and Simulink empower engineers to optimize workflows by enabling synthetic data generation, reduced-order modeling, and the integration of AI into embedded systems.

By allowing engineers to develop, test, and validate models before hardware implementation, these methods reduce costs, minimize risks, and accelerate innovation. As AI and simulation technologies continue to evolve, their impact on space applications will expand, shaping the future of exploration and industry.

Validate your login

Sign In

Create New Account